|

Program to rigid-tap a list of coordinates in a file. Program to drill a circular array of holes. Program to peck-drill a circular array of holes. Program to make a round pocket. Program to trepan a round pocket. Program to drill a rectangular array of holes. Program to machine a rectangular pocket. Program to machine the OD of a round post. Program to machine a outside of a rectangular post. Program to make spotting, drilling and rigid tapping programs from a file list of XY coordinates. Program to trepan a circular cutout with ramp down in Z. Program to trepan a rectangular cutout with ramp down in Z. Program to mill internal threads with a single-row thread mill. Program to machine a oval (race track) hole. All of these programs need to be compiled with a c compiler. On a Linux system with the compiler installed, create a file "compile" with this in it : cc $1.c -o $1 -lm make this file executable with : chmod u+x compile then compile these programs like this : ./compile filetap

|

| One of the first things I wanted to do was to bore circular holes in things. Whether you call these pockets or bored holes doesn't matter much. All the moves are made as climb milling passes, spiraling out from the center in quadrants of increasing radius, until the cutter has reached the finish pass allowance. It then plunges deeper, and repeats, until the full depth has been reached. On the last depth pass, the cutter spirals out further, completing the finish pass. it then returns to the hole center and retracts. |  |

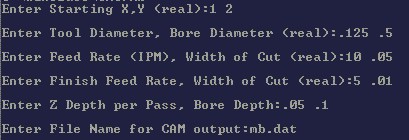

A screen copy of user's input to the program. |

N10 G01 F10.000 X1.0000 Y2.0000 N20 F1.667 Z-0.0500 N30 F10.000 X1.0125 N40 G03 X1.0000 Y2.0125 R0.0125 N50 X0.9750 Y2.0000 R0.0156 N60 X1.0000 Y1.9625 R0.0271 N70 X1.0500 Y2.0000 R0.0391 N80 X1.0000 Y2.0625 R0.0513 N90 X0.9250 Y2.0000 R0.0635 N100 X1.0000 Y1.9125 R0.0759 N110 X1.1000 Y2.0000 R0.0883 N120 X1.0000 Y2.1125 R0.1007 N130 X0.8750 Y2.0000 R0.1131 N140 X1.0000 Y1.8625 R0.1256 N150 X1.1500 Y2.0000 R0.1380 N160 X1.0000 Y2.1625 R0.1505 N170 X0.8250 Y2.0000 R0.1629 N180 X1.0000 Y1.8125 R0.1754 N190 X1.1775 Y2.0000 R0.1775 N200 X1.0000 Y2.1775 R0.1775 N210 X0.8225 Y2.0000 R0.1775 N220 X1.0000 Y1.8225 R0.1775 N230 X1.1775 Y2.0000 R0.1775 N240 G01 F10.000 X1.0000 Y2.0000 N250 F1.667 Z-0.1000 |

(Continuation of program) N260 F10.000 X1.0125 N270 G03 X1.0000 Y2.0125 R0.0125 N280 X0.9750 Y2.0000 R0.0156 N290 X1.0000 Y1.9625 R0.0271 N300 X1.0500 Y2.0000 R0.0391 N310 X1.0000 Y2.0625 R0.0513 N320 X0.9250 Y2.0000 R0.0635 N330 X1.0000 Y1.9125 R0.0759 N340 X1.1000 Y2.0000 R0.0883 N350 X1.0000 Y2.1125 R0.1007 N360 X0.8750 Y2.0000 R0.1131 N370 X1.0000 Y1.8625 R0.1256 N380 X1.1500 Y2.0000 R0.1380 N390 X1.0000 Y2.1625 R0.1505 N400 X0.8250 Y2.0000 R0.1629 N410 X1.0000 Y1.8125 R0.1754 N420 F5.000 X1.1875 Y2.0000 R0.1875 X1.0000 Y2.1875 R0.1875 X0.8125 Y2.0000 R0.1875 X1.0000 Y1.8125 R0.1875 X1.1875 Y2.0000 R0.1875 N430 G01 X1.0000Y2.0000 N440 G01 F50 Z0.1 N450 M02 |

These programs should be able to be compiled on Linux with Gcc, PC-DOS with Microsoft C, or Windows with Borland C. IF you have problems compiling them, let me know, and I'll see if we can solve the problem.

Download program makebore.c source or Download DOS Executable makebore.exe

Download program for arcs with I,J words or Download DOS Executable makebore with I,J words

| This program mills out a rectangular pocket in the material. If you are making the pocket go all the way through a thin sheet, you can use treprect, which doesn't waste time cutting the entire interior, it just cuts around the perimeter. This program figures out which axis has the longer travel, and then starts by cutting down the center of the pocket in that direction. It then 'spirals' out from there, by climb milling. It repeats this process at each depth until at the final depth, where it completes the pocket out to the finish dimensions. |  |

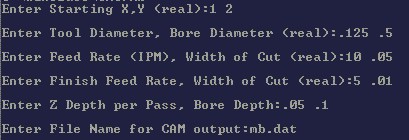

A screen copy of user's input to the program. |

N10 G01 F40.0 X2.5000 Y2.2750 N20 Z0.0200 F40 N30 Z-0.1000 F2.0 N40 Y5.7250 F5.0 N50 X2.2500 F10.0 N60 Y2.2750 N70 X2.7500 N80 Y5.7250 N90 X2.0000 F10.0 N100 Y2.2750 N110 X3.0000 N120 Y5.7250 N130 X1.7500 F10.0 N140 Y2.2750 N150 X3.2500 N160 Y5.7250 N170 X1.5000 F10.0 N180 Y2.2750 N190 X3.5000 N200 Y5.7250 N210 X1.2750 F10.0 N220 Y2.2750 N230 X3.7250 N240 Y5.7250 N250 X2.5000 F40.0 N260 Y2.2750 N270 Z-0.2000 F2.0 N280 Y5.7250 F5.0 N290 X2.2500 F10.0 |

(Continuation of program) N300 Y2.2750 N310 X2.7500 N320 Y5.7250 N330 X2.0000 F10.0 N340 Y2.2750 N350 X3.0000 N360 Y5.7250 N370 X1.7500 F10.0 N380 Y2.2750 N390 X3.2500 N400 Y5.7250 N410 X1.5000 F10.0 N420 Y2.2750 N430 X3.5000 N440 Y5.7250 N450 X1.2750 F10.0 N460 Y2.2750 N470 X3.7250 N480 Y5.7250 N490 X2.5000 F40.0 N500 Y2.2750 N510 F5.0 Y2.2563 N520 Y2.2500 X3.7500 N530 Y5.7500 N540 X1.2500 N550 Y2.2500 N560 X3.7500 N570 Z0.1000 N580 M02 |

Download program rectpocket.c OR Download DOS Executabe rectpocket.exe

| This program mills a rectangular cutout all the way through the material. It makes a complete path such that the cutter leaves a finish allowance on the inside of the desired dimensions, and then pauses to allows you to remove the 'blank' form the hole. You then resume the program and the cutout is brought up to the desired dimension. |  |

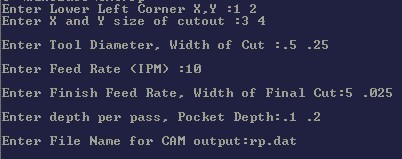

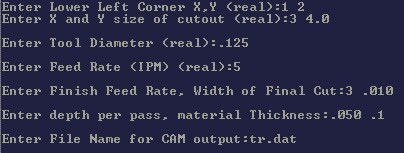

A screen copy of user's input to the program. |

N10 G01 F5.0 X1.0725 Y2.0725 N20 Z-0.0500 N30 X3.9275 N40 Y5.9275 N50 X1.0725 N60 Y2.0725 N70 Z-0.1000 N80 X3.9275 N90 Y5.9275 N100 X1.0725 N110 Y2.0725 N120 F3.0 X1.0650 N130 X1.0625 Y2.0625 N140 M01 (Remove blank) N150 X3.9375 N160 Y5.9375 N170 X1.0625 N180 Y2.0625 N190 Z0.1000 N200 M02 |

Download program treprect.c OR Download DOS Executable treprect.exe

Here's a variation on this program to ramp down while cutting the outline of the pocket. Download program treprectramp.c OR

| This program drills holes in a circular pattern. It can do the first n of a pattern of m holes (ie. first 5 out of 6). The first hole is always at Y=Ycent+radius, X=center. If you want to omit specific holes, it is easy to edit them out of the generated G-code file. |  |

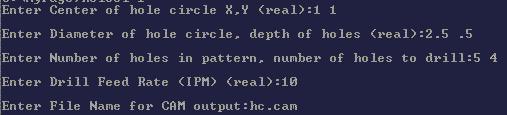

A screen copy of user's input to the program. |

N10 G01 F30 X1.0000 Y2.2500 N20 F10.00 Z-0.5000 N30 F30 Z0.1000 N40 G01 F30 X2.1888 Y1.3863 N50 F10.00 Z-0.5000 N60 F30 Z0.1000 N70 G01 F30 X1.7347 Y-0.0113 N80 F10.00 Z-0.5000 N90 F30 Z0.1000 N100 G01 F30 X0.2653 Y-0.0113 N110 F10.00 Z-0.5000 N120 F30 Z0.1000 N130 F30 X1.0000 Y1.0000 N140 M02 |

Download program holecircle.c OR Download DOS Executable holecircle.exe

| This program drills holes in a circular pattern, as above, but using a peck drilling cycle. |  |

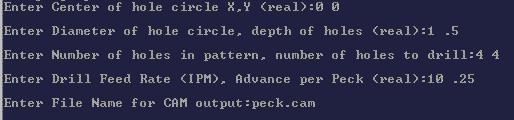

A screen copy of user's input to the program. |

N10 G01 F30 X0.0000 Y0.5000 N20 F50.00 Z 0.0100 N30 F10.00 Z-0.2500 N40 F50.00 Z0 N50 F50.00 Z -0.2400 N60 F10.00 Z-0.5000 N70 F50.00 Z0 N80 F30 Z 0.1000 N90 G01 F30 X0.5000 Y-0.0000 N100 F50.00 Z 0.0100 N110 F10.00 Z-0.2500 N120 F50.00 Z0 N130 F50.00 Z -0.2400 N140 F10.00 Z-0.5000 N150 F50.00 Z0 N160 F30 Z 0.1000 N170 G01 F30 X-0.0000 Y-0.5000 |

(Continuation of program) N180 F50.00 Z 0.0100 N190 F10.00 Z-0.2500 N200 F50.00 Z0 N210 F50.00 Z -0.2400 N220 F10.00 Z-0.5000 N230 F50.00 Z0 N240 F30 Z 0.1000 N250 G01 F30 X-0.5000 Y0.0000 N260 F50.00 Z 0.0100 N270 F10.00 Z-0.2500 N280 F50.00 Z0 N290 F50.00 Z -0.2400 N300 F10.00 Z-0.5000 N310 F50.00 Z0 N320 F30 Z 0.1000 N330 F30 X0.0000 Y0.0000 N340 M02 |

Download program peckcircle.c OR Download DOS Executable peckcircle.exe

| This program mills threads into a hole that has already been drilled. It is designed for use with single-row thread mills, which have the advantage that they can make threads with a wide pitch range. The disadvantage is they only mill one turn of the thread at a time. (This program will actually work with standard thread mills, too, you just specify a depth equal to a little more than one turn.) |  |

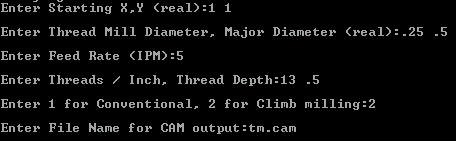

A screen copy of user's input to the program. |

N10 G01 G17 G90 F30 X1.0000 Y1.0000 N20 Z-0.5000 N30 F5.000 X1.1250 N40 G03 X0.8750 I-0.1250 Z -0.4615 N50 G03 X1.1250 I0.1250 Z -0.4231 N60 G03 X0.8750 I-0.1250 Z -0.3846 N70 G03 X1.1250 I0.1250 Z -0.3462 N80 G03 X0.8750 I-0.1250 Z -0.3077 N90 G03 X1.1250 I0.1250 Z -0.2692 N100 G03 X0.8750 I-0.1250 Z -0.2308 N110 G03 X1.1250 I0.1250 Z -0.1923 N120 G03 X0.8750 I-0.1250 Z -0.1538 N130 G03 X1.1250 I0.1250 Z -0.1154 N140 G03 X0.8750 I-0.1250 Z -0.0769 N150 G03 X1.1250 I0.1250 Z -0.0385 N160 G03 X0.8750 I-0.1250 Z-0.0000 N170 G03 X1.1250 I0.1250 Z 0.0385 N180 G01 X1.0000 Y1.0000 N190 G01 F50 Z0.1 N200 M02 |

Download program threadmill.c OR Download DOS Executable threadmill.exe

| This program works very similarly to makebore, but instead of milling away from the center of the hole or pocket, it starts near the edge, and just mills away a little more than the width of the tool, making a finish pass on the OD. This is most useful for cutting large holes out of sheet material, as you don't waste time turning the blank into chips, but just let it drop out. |

Download program makering.c OR Download DOS Executable makering.exe

| This program works very similarly to makering, but makes the finishing pass toward the center, thereby leaving a round post at the center coords. The operation should be obvious, as it is very like the previous programs. |

Download program makepost.c OR Download DOS Executable makepost.exe