PPMC Encoder Board

Features :

The Parallel Port Motion Control Encoder board has 4 24-bit

quadrature encoder counters. The board provides up to 200 mA

at 5V to each of the 4 encoders through resettable (PTC)

fuses.

There are two versions of the encoder board available, one supports

only single-ended encoder inputs, the other will support both

single-ended and differential encoders in any combination.

The choice between single-ended and differential inputs is

made through jumpers, on a channel by channel basis.

The Encoder is capable of generating a servo cycle clock

that can be selected under software control from 625 Hz to 10 KHz

in 16 steps (10 KHz divided by a factor of 1 to 16). This

clock can be provided to additional encoder boards and DAC16

boards, so all encoders and DACs sample and update synchronously.

The encoder board occupies a block of 16 consecutive addresses on the

EPP (IEEE 1284 protocol) bus. The high 4 address bits are

specified through a 4-position DIP switch marked SW1.

The Most significant bit (bit # 7) is switch 4, the least significant

fixed address bit (bit # 4) is switch 1.

Connectors :

P2 through P5 connect to the encoders.

P2 is for channel 0, the first Axis. P5 is for channel

3, the last Axis. With the component side of the board

UP, and these connectors facing you, pin 1 is on the

Left. Pins are as follows :

| Pin # | Signal |

| 1 | +5 V |

| 2 | Ground |

| 3 | A |

| 4 | B |

| 5 | Z |

| 6 | A/ | Differential Only |

| 7 | B/ | Differential Only |

| 8 | Z/ | Differential Only |

| A and B are the quadrature signals from the

encoder. If you have an encoder with an index

channel, this is connected to the Z input.

For differential encoders, the A/ B/ and Z/

inputs are used for the complemented signals.

|

| JP13 is factory set for normal operation. It can

be broken to allow downloading the FPGA program

from a computer during debugging. With the jumper

in the factory (closed) state, the FPGA downloads its

program from the SPROM in U2. A failure of the

FPGA program to correctly load is indicated by a

steadily lit LOAD FAIL LED. If the program does

not load correctly (this should not happen in the field)

it could be due to slow or erratic rising of the

+5 V power supply.

|

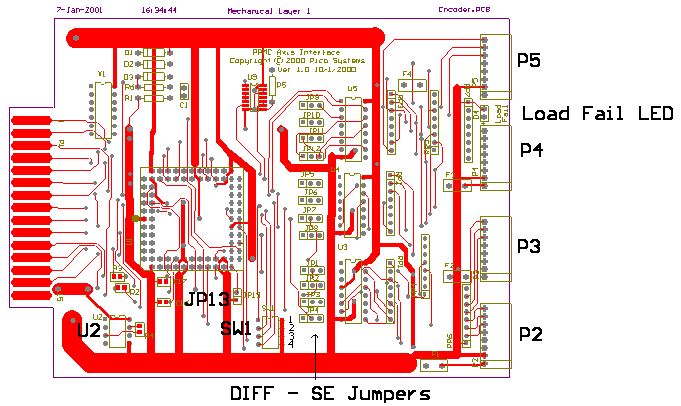

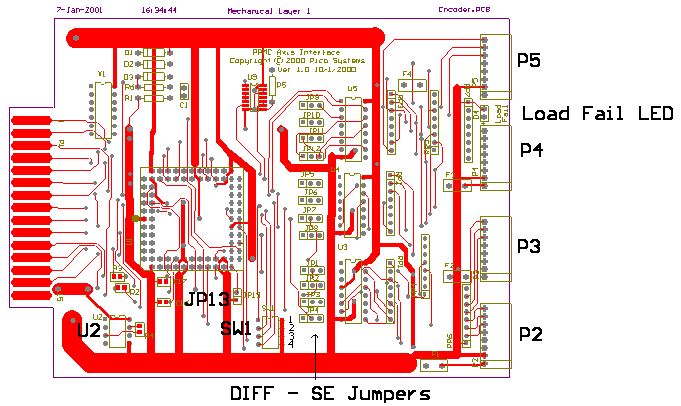

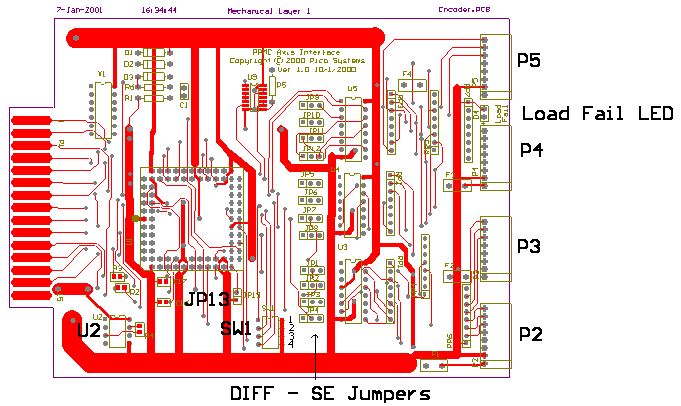

On boards which have the differential input option,

the following jumper positions are used to select

input mode for individual channels. Single-ended

is selected with the jumpers to the left (as the board

is shown in the drawing below), and differential

is selected with the jumper to the right.

| Channel # | Jumpers |

| 0 | JP1, 2 & 3 |

| 1 | JP4, 5 & 6 |

| 2 | JP7, 8 & 9 |

| 3 | JP10, 11 & 12 |

|

|

Board Layout Board Layout |

|

To Home

Board Layout

Board Layout  Board Layout

Board Layout